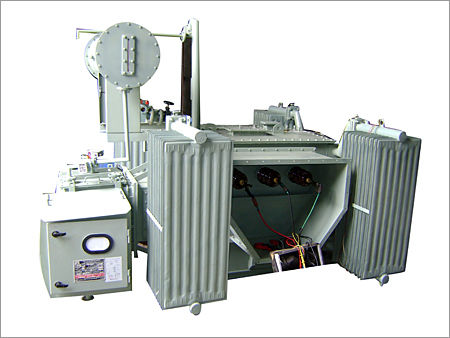

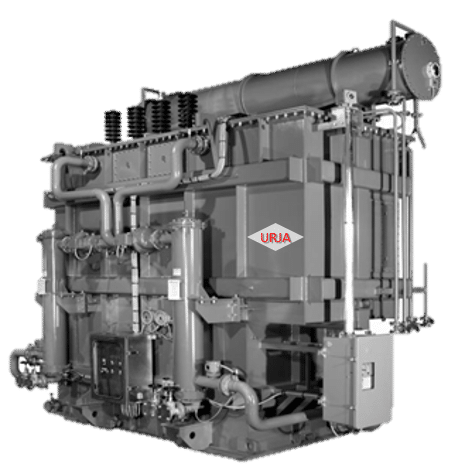

Furnace Transformer

Product Details:

- Cooling Type Oil Natural Air Natural (ONAN)/ Oil Natural Air Forced (ONAF)/ Oil Forced Air Forced (OFAF)/ Oil Forced Water Forced (OFWF)

- Product Type Oil Immersed

- Material Copper

- Output Product wise

- Frequency (MHz) 50 Hertz (HZ)

- Efficiency 99.9%

- Phase Three Phase

- Click to View more

Furnace Transformer Price And Quantity

- 1 Unit

Furnace Transformer Product Specifications

- Product wise

- Oil Immersed

- 50 Hertz (HZ)

- 99.9%

- Copper

- Oil Natural Air Natural (ONAN)/ Oil Natural Air Forced (ONAF)/ Oil Forced Air Forced (OFAF)/ Oil Forced Water Forced (OFWF)

- Three Phase

Furnace Transformer Trade Information

- 100 Unit Per Month

- 2-3 Months

- Australia, Eastern Europe, Middle East, South America, Western Europe, Asia, Central America, North America, Africa

- All India

- Bureau of Indian Standards (BIS) , Bureau OF Energy Efficiency (BEE)

Product Description

By providing the range of performance driven transformer we are also engaged in the constructing Furnace Transformers. As it is known that transformers are designed in a way that can provide suitable voltage to match the heating element requirements. These electronic devices can be utilized as arc, ladle, induction, submerged arc with the range of upto 10 MVA and 33kV. Within the transformer enclosure by having the low voltage windings arranged in the closed delta configuration a high current furnace transformer is provided. In this system bus bar terminals provide the electrical connection with the low voltage windings. Unlike other transformers, Furnace Transformers are installed to step down the voltages from 11 and 33 kV to levels of several hundred volts only which gives the result in form of massive secondary currents. For higher secondary currents special kinds of bushes are needed to connect the bus bars. Most of the Furnace bus bars are water cooled, the material used in the fabrication of winding is copper.

Owing to our technical advanced infrastructure base & profound industry expertise, we are noted as the profound manufacturer & exporter of High Current Furnace Transformer. Manufactured by us using tested quality materials & components, these furnace transformers are offered to our clients at feasible prices. For ensuring its quality & performance, these furnace transformers are duly checked by us on diverse quality parameters. High Current Furnace Transformer is widely used in electrical & electronic industries.

Initially the Furnace Transformers are located close to the furnace in the single phase units arranged around it in a triangular form. This increases the risk of fire, which encourages the single phase units due to the structural limitations of the buildings. Main functions of this Furnace Transformers to provide the suitable voltage to match heating element requirements. This high frequency transformers can be used to serve various induction heating process. These devices are widely installed in number of industrial sectors from Electronics, Renewable Energy, Pharmaceuticals, Chemicals, Wind Mill Farms, Construction to Automotive. These devices are associated with the open arc furnaces which can be subjected to a number of short circuits as the materials being melted collapses across the electrodes. This robustly constructed transformer has the ability to withstand various effects. Minimum impedance values for furnace transformers of the core type are in the order of 4 -5 %.

Features of High Current Furnace Transformer:

- Durability.

- Supreme value.

- Corrosion opposition.

- Very good functionality rate.

- Very good finish of dust coating.

- Step-up and Step-down transformers constructed.

- Accessible as absolutely self defended (csp) type.

- Conceived to meet customized specifications as per obligation.

- Sturdy & Steely conceive to take care of frequent short circuits.

- Adept to withstand Impulse Voltage and Short Circuit checks as per IS/IEC.

- Accessible as Corrugated Hermetically Sealed kind which is compact in size.

- Constructed with prime CRGO using step-lap conceive for reduced deficiency.

- Broad process of wrinkle and siccative of coils producing in a robust construction.

- Diverse ratings type tested from National Accreditation Board for checking and Calibration Laboratories (NABL) accredited labs.

- Gas factories

- Steel plants

- Calcium carbide industries

Specifications:

- OFWF chilling with ONAN chilling optional.

- ONAN chilling with accepted pressed steel radiators

- Designed to withstand the harmonics developed due to furnace procedure.

- "Off Circuit Manually Operated" and "On Load Tap Changer" (OLTC) with AVR and RTCC section.

- Requisite sequence reactors for arc furnace transformers to reduce the short circuit tensions generated in transformer during the furnace operation

- 'Tap Changer' choices accessible in these furnace transformers, arc furnace transformers and electric powered arc furnace transformers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese